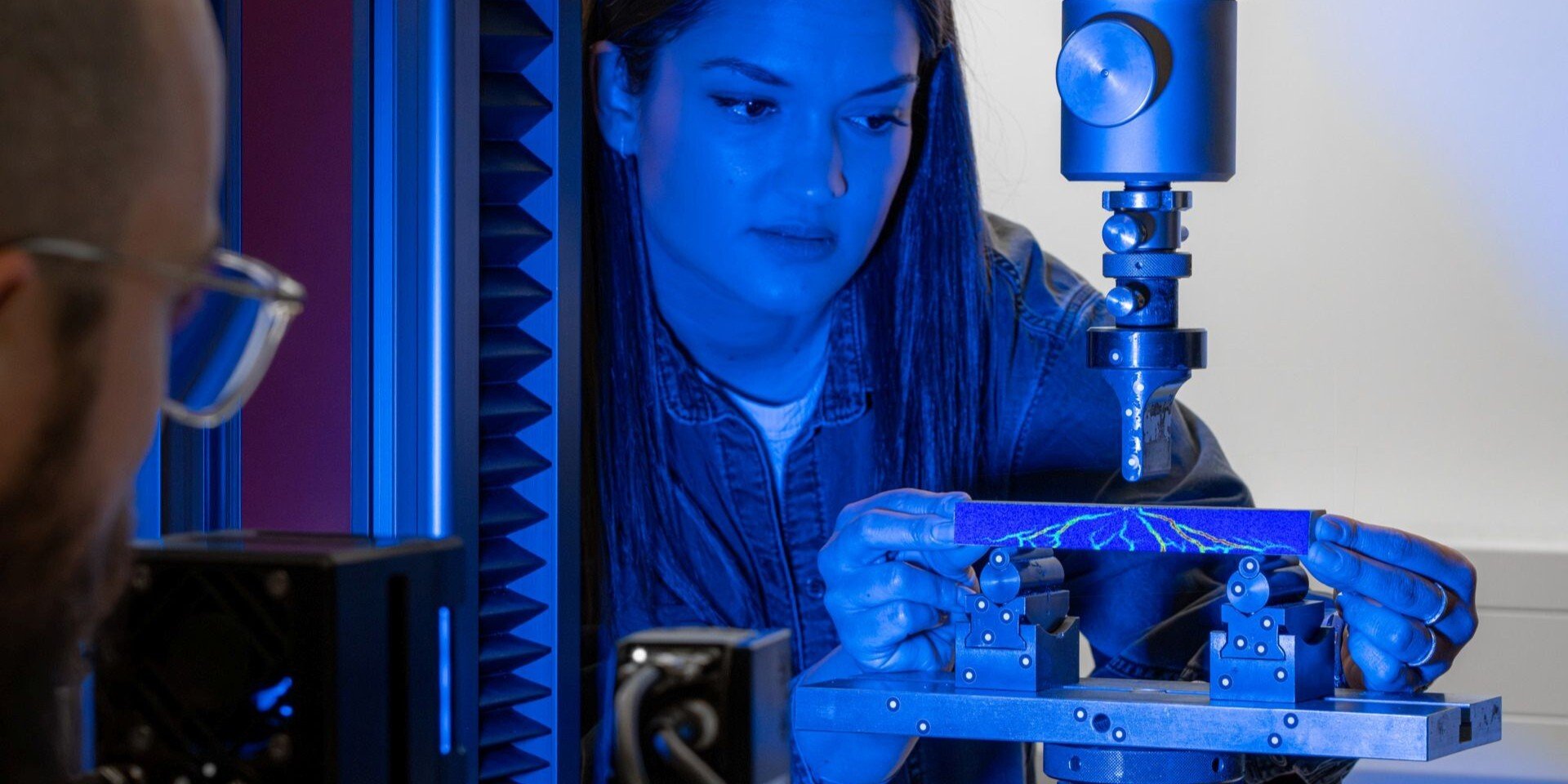

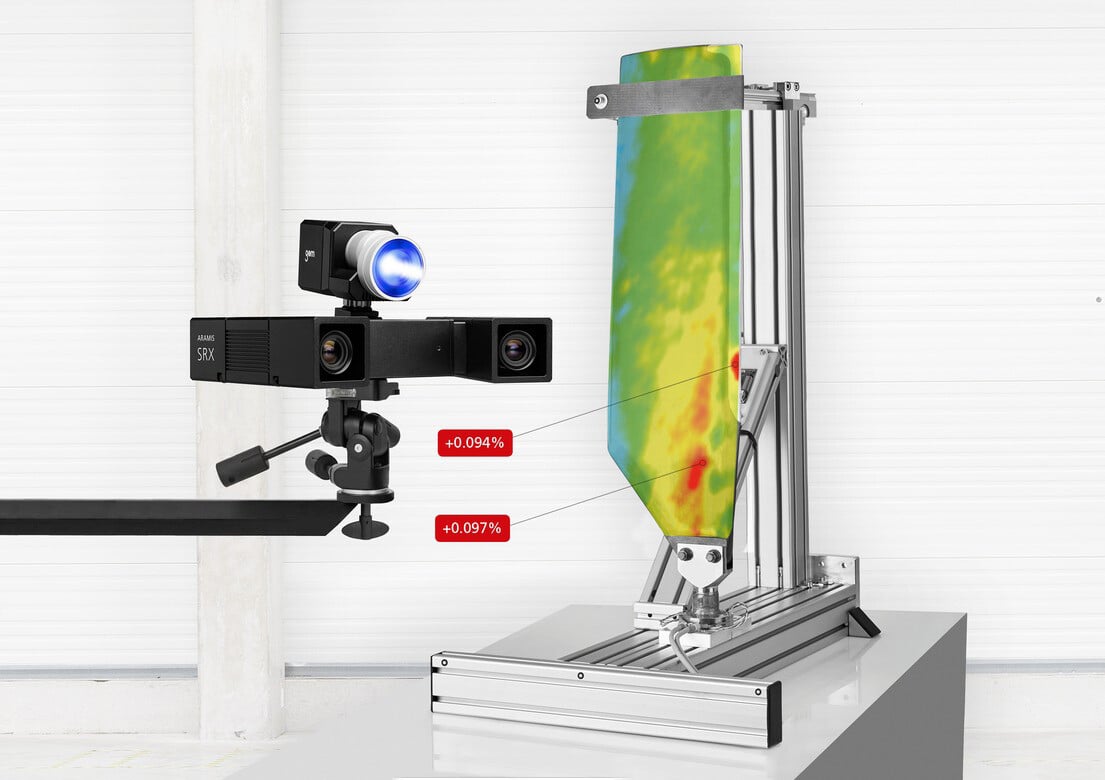

Our integrated stereo-camera systems provide ultimate ease-of-use to measure strains and displacements with a variety of materials.

15:36, Feb 24

15:19, Feb 19

ARAMIS 3D-DIC is the ideal tool for measuring material properties to most ASTM and ISO standards.

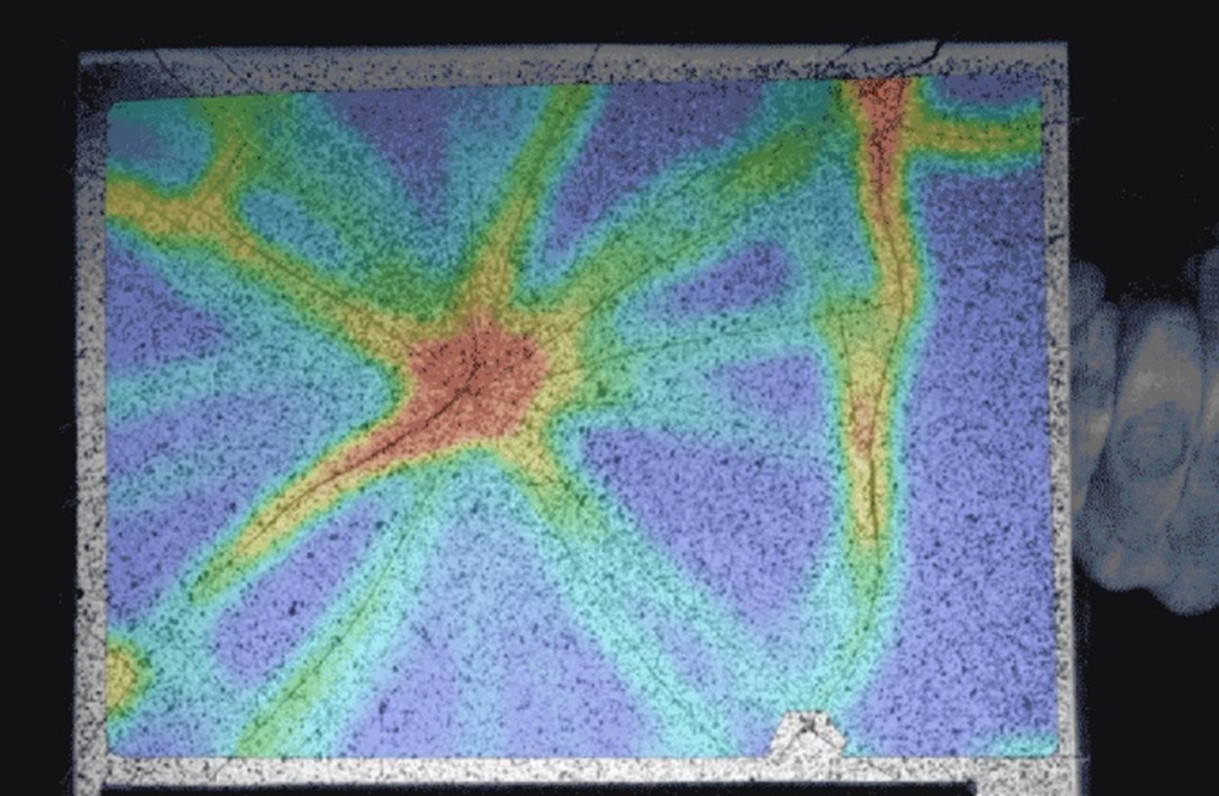

Full-field component testing that measures all points for direct FEM comparison to the real multi-material, structural response

ARAMIS Optical Strain allows for a holistic understanding of the structural response of your test structures.

ARAMIS 3D High-Speed combines high-speed cameras with our powerful ZEISS Inspect software to measure components at any speed, for high strain rate materials testing, vibration analysis, and impact testing.

ARAMIS can be synchronized with a thermal imaging camera to capture temperature information. The temperature data can be imported, aligned, and mapped in 3D coordinates directly to the inspection.

For precise fixture alignment and assembly in 6-DOF (degrees of freedom).

Feb 24, 2026

Feb 19, 2026

Dec 15, 2025