Structural Testing

Engineering Services

Providing You With The Most Insightful Data.

Let's Work Together

Trilion Engineering Services is the perfect solution for solving complicated applications and/or developing methods for critical measurements, providing precision data. We provide experienced engineers, with industry-specific experience in aerospace, automotive, microelectronics, civil, power, biomechanics, and consumer products.

Structural Testing Services

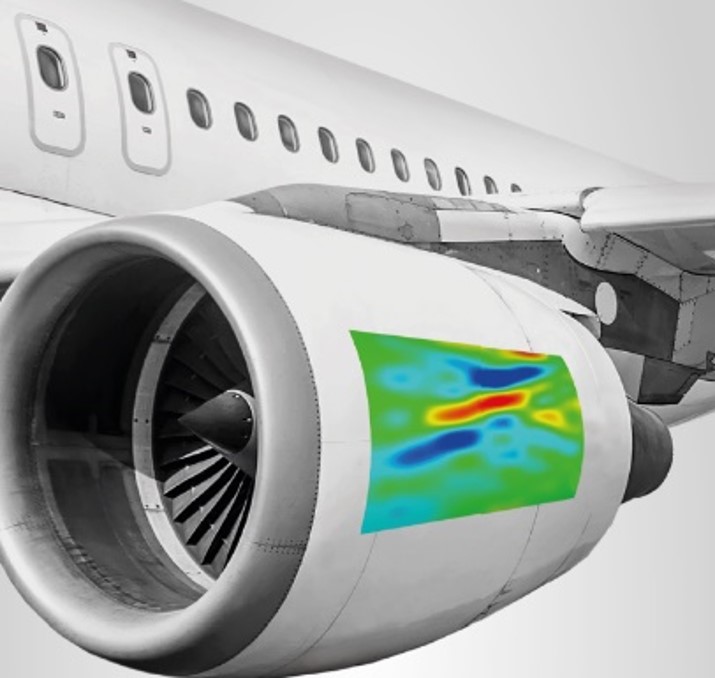

Aerospace

Optical Strain is ideal for measuring dynamic structure response of your aerospace testing and provides a holistic understanding of components under test. It takes tens of thousands of measurement points.

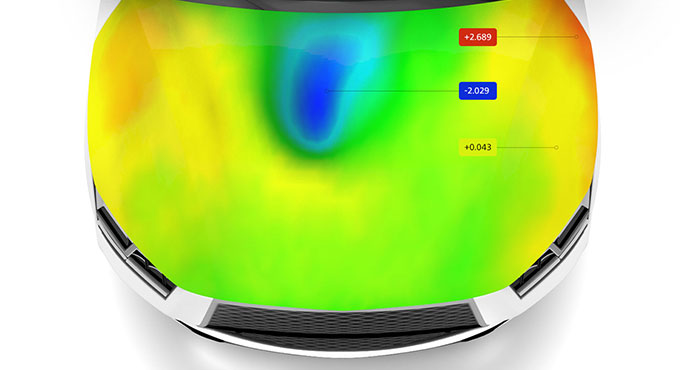

Automotive

Digital Image Correlation (3D-DIC) and Dynamic 3D Photogrammetry provides precision measurements of real, complex materials and structures, making it the perfect tool in automotive testing.

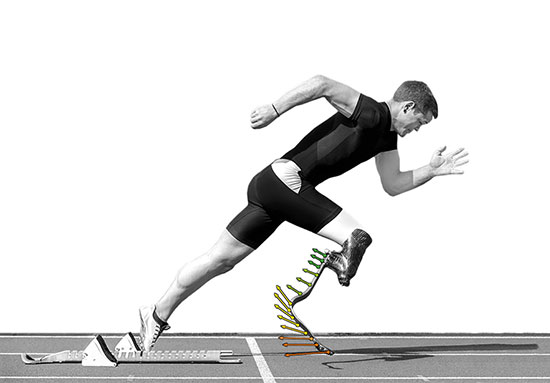

Biomechanics

Optical 3D metrology has been established in the biomechanics and medical device industry for dynamic analysis of everything from implants and prostheses to bones, tendons, and ligaments.

Civil Engineering

With ARAMIS, the user can make a baseline measurement of a structure & monitor its health over a period of time. This will allow you to observe the structural integrity as it is exposed to environmental conditions, & standard loads.

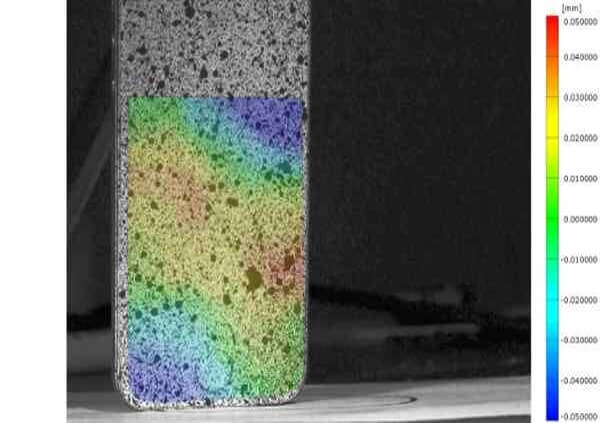

Electronics & Consumer Goods

ARAMIS has countless applications for fields of view down to 100 microns. ARAMIS can capture and analyze strain and displacement data from thermal cycling, fatigue, warpage, and impact damage.

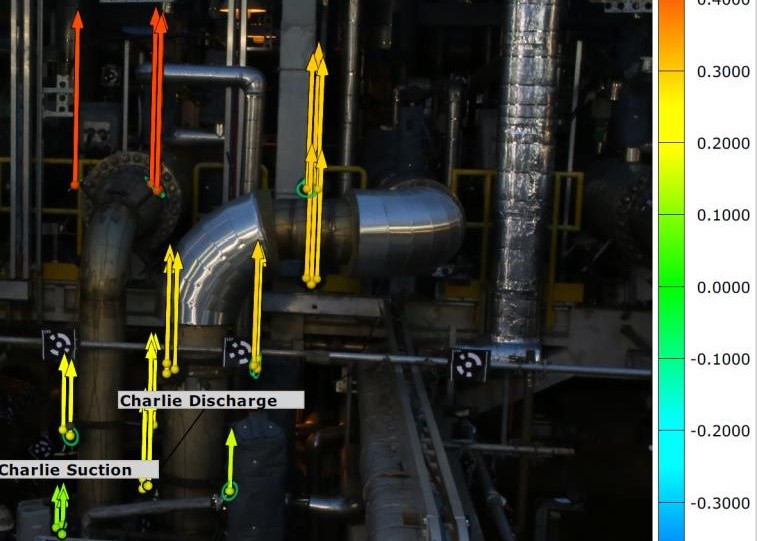

Oil, Gas, & Energy

ARAMIS, can detects micromotion of pumps & motors relative to baseplates for validation of hot alignment procedures, optically acquire multiple data points for FFT analysis, & capture strain data at thousands of points along any component.

Thermography/Thermal Expansion

ARAMIS Thermography is unique in its ability to read full-field temperatures in 3D coordinates. This provides broad capabilities in understanding your materials, structures, and processes. Optical Strain measurement uses the changes in temperature during a test to correct the total strain measurements for thermal expansion and to measure the true mechanical strains.

Stand Out Structural Testing Services

Structural Testing Services in the Aerospace Industry

○ Photogrammetry Measurements During Space Shuttle Tanking Test

○ Monitoring the Dynamics of a Helicopter Main Rotor with Stereophotogrammetry

○ Performance Verification of 3D Image Correlation Using Digital High-Speed Cameras

Structural Testing Services in the Automotive Industry

○ Measuring Tire Shape with Projected Stochastic Pattern

Structural Testing Services in the Biomechanics Industry

○ The Ultimate Biomechanics Tool for Displacements and Strain Testing

Structural Testing Services in the Civil Engineering Industry

○ Full Field Deformation Measurements During Seismic Loading of Masonry Buildings

○ Application of Three-dimensional Digital Image Correlation to the Core-drilling Method

Structural Testing Services in the Consumer Goods Industry

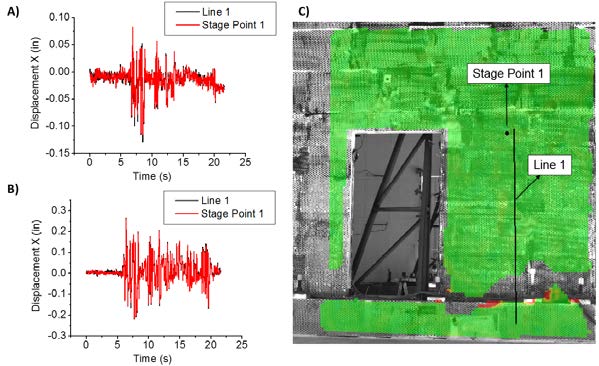

○ AN1703 ODS Analysis Utilizing Optical Metrology

○ Small Device Battery Measurements With DIC A Multi-view Test Methodology

Jaw-dropping Data is just a Call Away

We Also Offer

System rental

If you don't have the budget for a system or only need to use our system for a one-time application. Renting one of our systems is the perfect option for you! Renting gives you the flexibility to always have the perfected system for your specific test.

RENT-TO-OWN (LONG TERM LEASE)

If you need more purchasing flexibility, we have long-term rental programs which let you apply the entirety of every payment to the purchase balance. Ask your Technical Account Manager about our rent-to-own program.

"Any university that is not teaching DIC is in the dark ages."

"If you invest the time, money, and hardware then you need to do the other 10% and be around people with the seat time and be in the atmosphere where you can draw from the experiences of the seasoned user."

"The full-field ARAMIS Optical Strain data is intuitively understood. We now analyze the full-field data, and there are no arguments about the results. It is intuitively obvious what is occurring to our structures."

"You acquired an ARAMIS system for composite buckling studies, what are you using it for now?" He responded, "Everything"

Its your last chance!

Nah... Not really. But you knew that. Here is a nice form in case you'd like to talk to one of our team and determine what services we can provide to you and your team.