Turbine, Pump, Blade, Generator, Silos, Ship-hull Testing

Improve equipment reliability

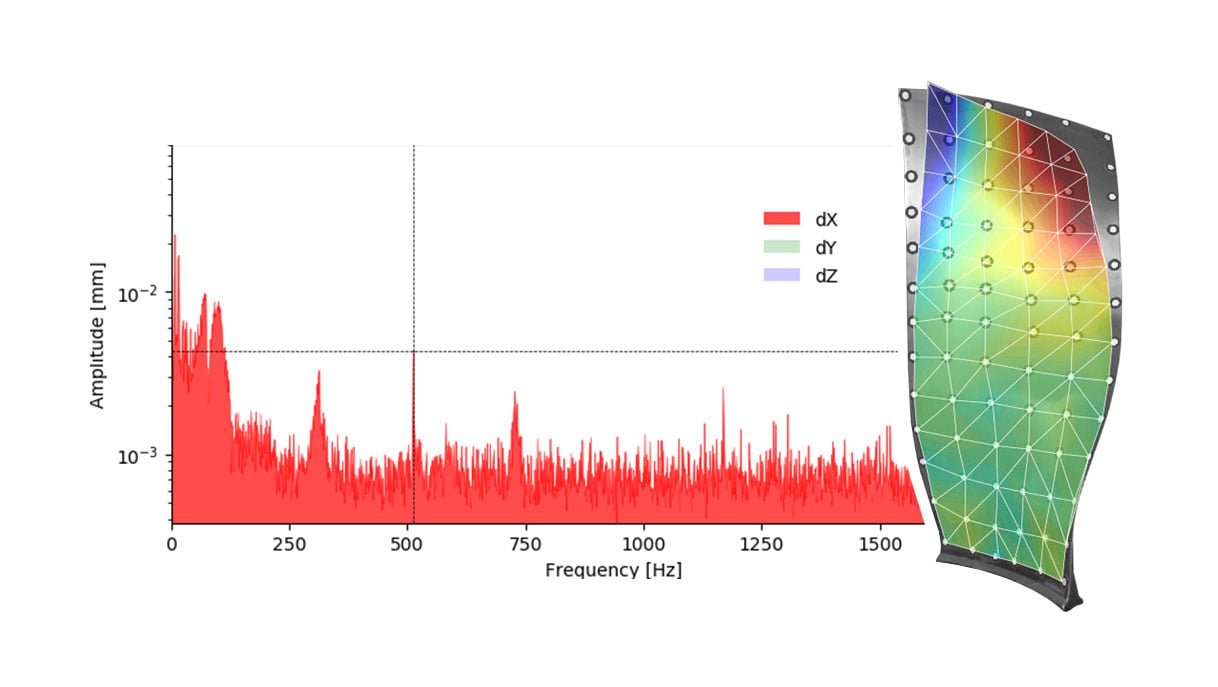

How ARAMIS & TRITOP Help Make Equipment Reliable

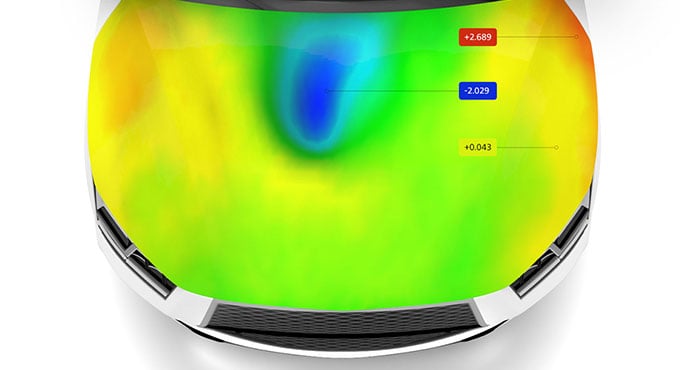

ARAMIS is allowing unprecedented insight into the operation of hydraulic systems with full-field strain and displacement measurements. With ARAMIS, users can detect micromotion of pumps and motors relative to baseplates for validation of hot alignment procedures, optically acquire multiple data points simultaneously for FFT analysis, and capture accurate strain data at thousands of points along any component.

For larger-scale system measurements and long-term structural health monitoring, TRITOP is the ideal tool. It is both time and scale-independent, permitting a user to perform measurements on components of any size over any amount of time. These capabilities make TRITOP perfect for measuring the effects of long-term fatigue and thermal expansion on very large components.

Maintaining & Assuring the Structural Health of Pipelines

The oil and gas industry is undoubtedly full of engineering challenges, but maintaining and assuring the structural health of pipelines to transport precious refined or raw products is a challenge of utmost importance. Unfortunately, the environment unwaveringly ignores our best attempts at designing and installing these pipelines to maximize their useful lifetime. As such, it’s prevalent for underground pipes to be subject to large rocks and roots pushing against their walls. These growing defects can jeopardize the structural health of a pipeline, and any failure can be catastrophic for the environment.

Using ARAMIS optical strain to measure pipeline defects can save the oil and gas industry a lot of time and money and prevent any catastrophic failure of pipelines. Read more about how ARAMIS is making a significant impact in the oil and gas industry!

Wind Turbine Blade Testing has never been easier.

Discover why the Technical University of Denmark and others use optical testing solutions like ARAMIS and TRITOP.

Product highlight

Our TRITOP Photogrammetry system is extremely reliable and was designed with large-scale testing in mind. It's a single camera system that offers unparalleled ease of use and precision.

Find out more

2 min read

Using Digital Image Correlation for Jet Aircraft Engine testing

Jul 9, 2024 by Walter Schnapp

1 min read

Finite Element Measurements for Reality in Composites

Apr 26, 2024 by Ben Eisdorfer

1 min read

Deformation Measurements During Seismic Loading of Masonry Buildings

Apr 24, 2024 by Ben Eisdorfer

Webinar: How to Automate Material Testing and Batch Process Data

March 25, 2024, Virtual

Learn more »Revolutionizing Testing with Optical Strain: Workshop at LIFT

August 6, 2024, Detroit, MI

Learn more »Testing with DIC: Workshop at Stress Engineering Services

August 20, 2024, Cincinnati, OH

Learn more »Want to learn more?

Our team can discuss and demonstrate most of our products and applications virtually to you today!