Xi Analytics

A Manufacturing Revolution

RESULT BASED

Next-Generation Product Testing And Development

Trusted by Fortune 500 companies across a dozen industries.

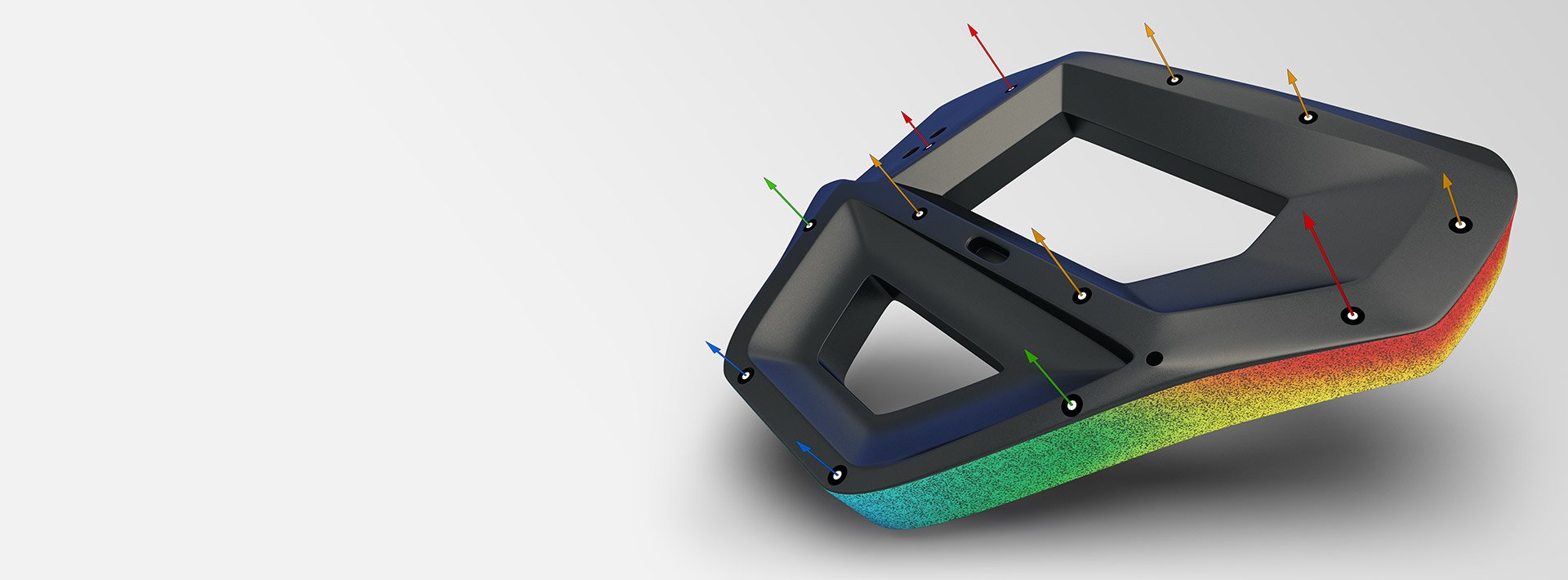

Tool-less assembly

No need to design, build and store physical tools

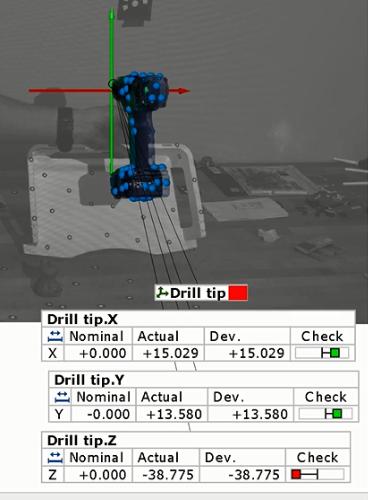

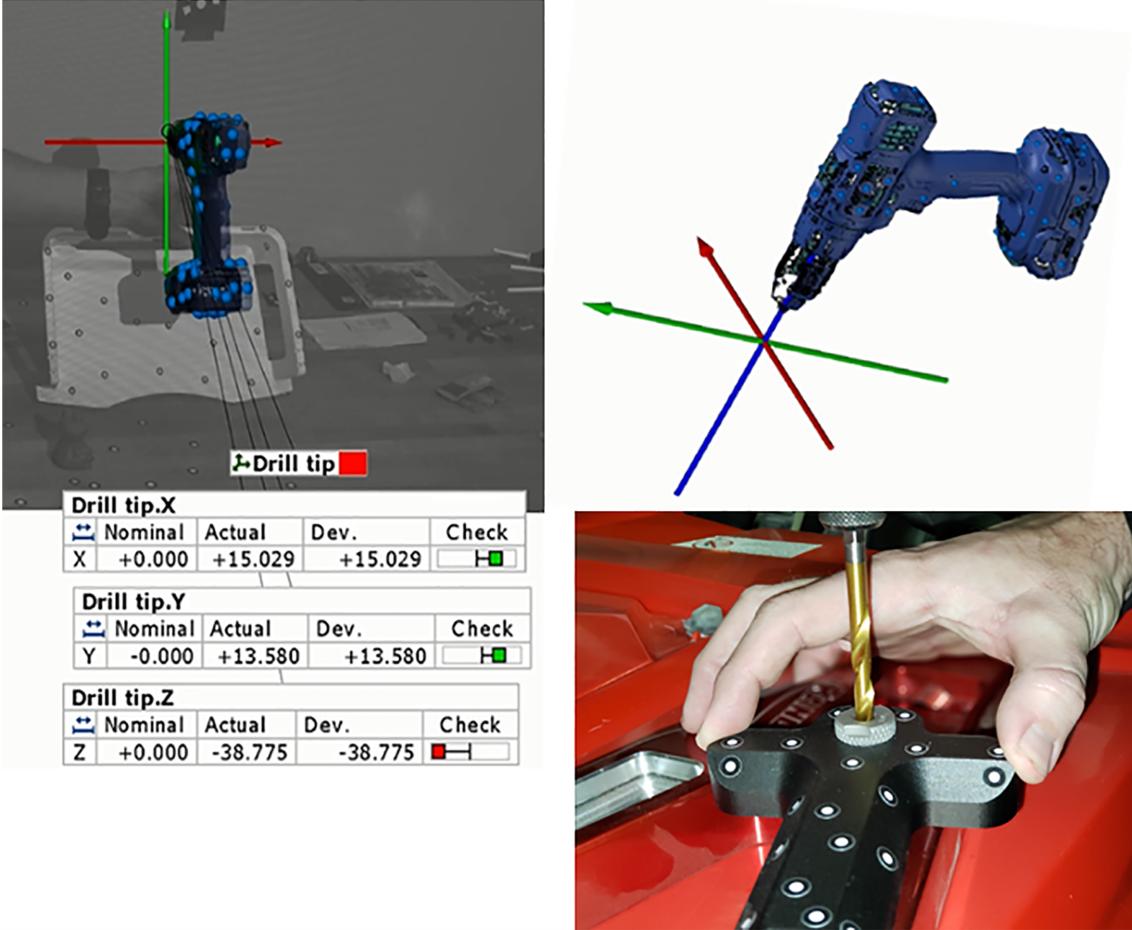

Digital Drilling

Each hole to be drilled is tracked to precise CAD dimensions, even on complex 3D parts, with Smart Tools. Blind holes can be drilled precisely, relative to reference structures, in true vehicle coordinates.

RVAT Kiosk for PONTOS Live

Build directly from CAD

60% faster than traditional hard tooling

QA (quality assurance) built-in

Precise positioning of components in 6-DoF (degrees of freedom)

Documenting as-built for your Digital-Twin

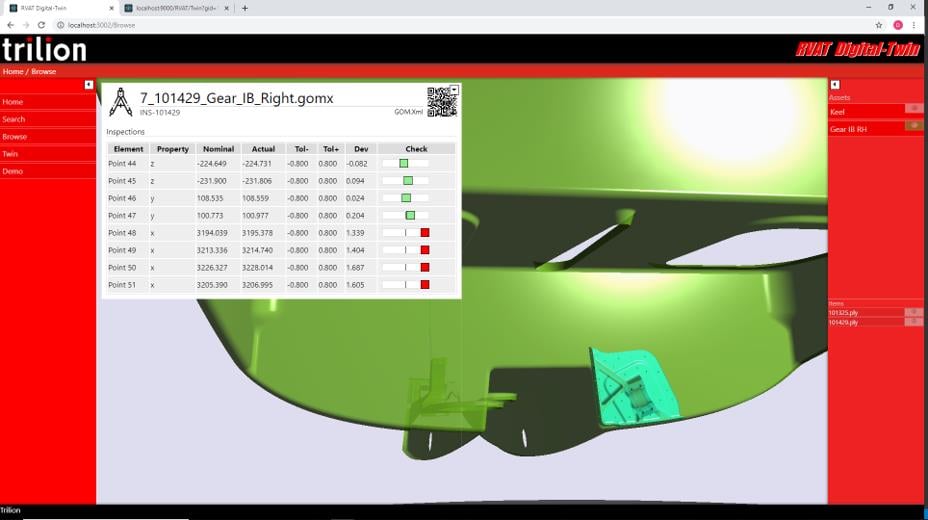

Xi Digital Twin

The Digital Thread records the As-Built details, QA, and testing to complete the Digital Twin and store it on the Xi Server for easy access and searchability.

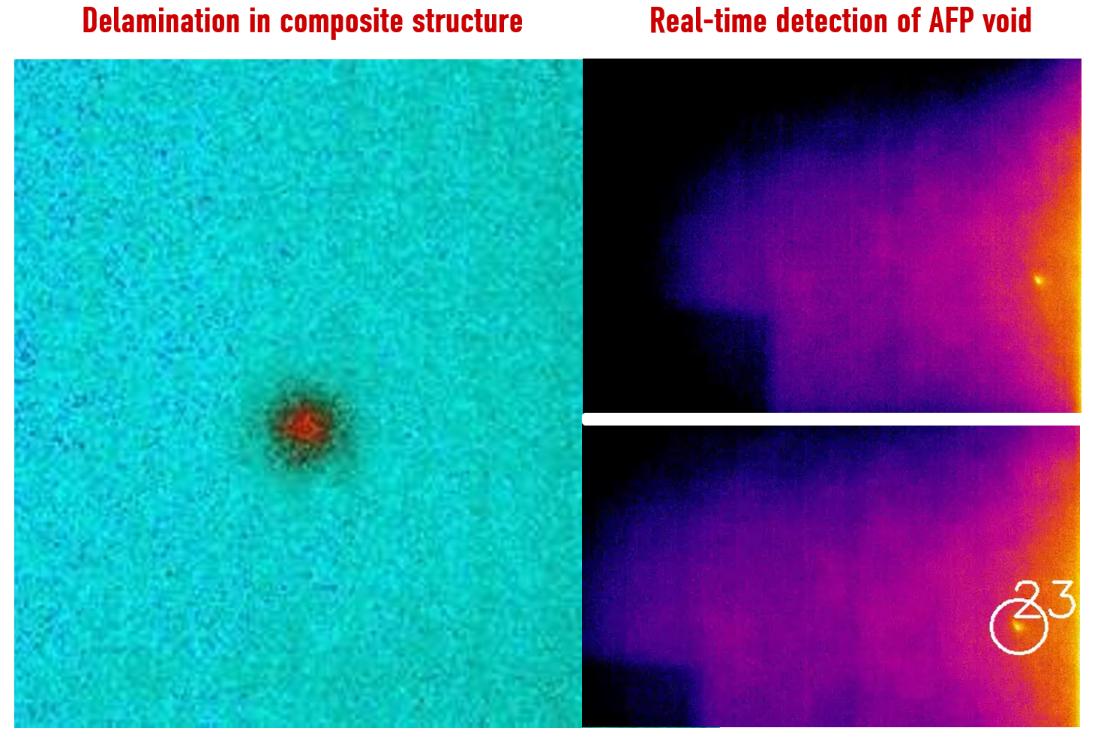

CoolScan Layup NDE

Voids, bridging and FOD can be detected before curing with our InSitu NDE during the layup to significantly improve product quality, ensuring high grade parts every time, and documenting these QA digital-threads for part validation.

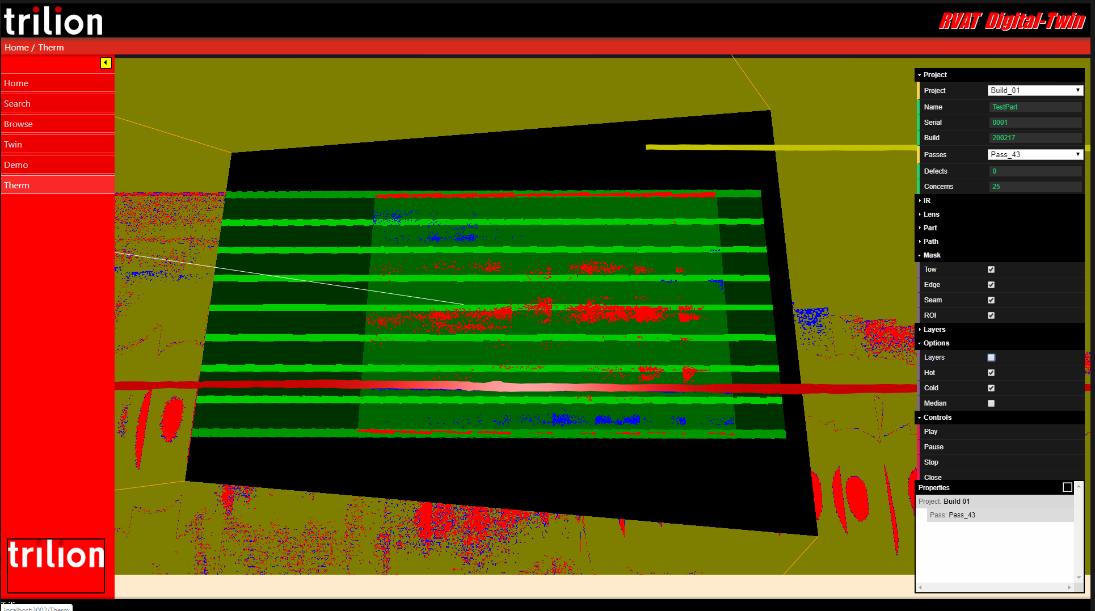

InSitu AFP Layup NDE

Lap/gap, twist, porosity, voids and FOD can be detected in real-time with our InSitu NDE to detect problems during the AFP layup. There they can be immediately corrected to improve product quality and efficiency while reducing waste.

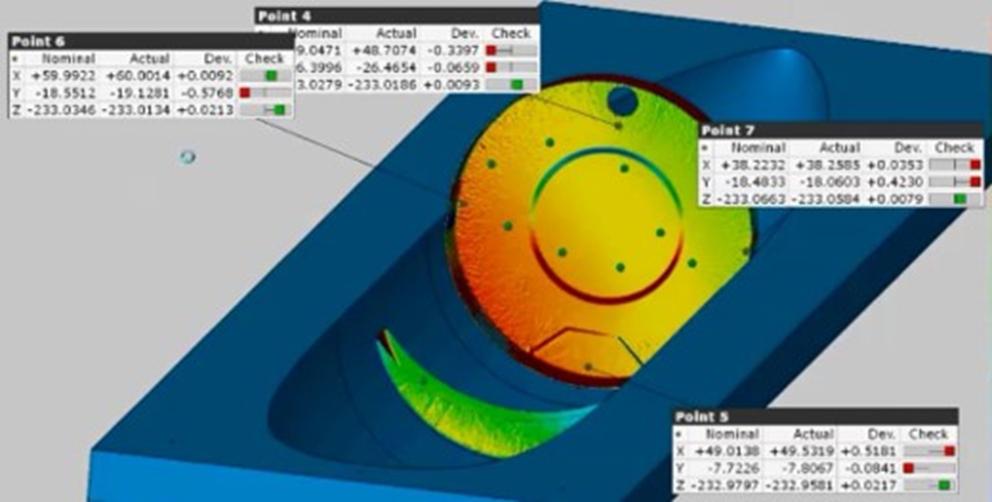

SmartTools

SmartTools allow the 3D optical tracking of standard or custom tools for precise positioning in true 3D CAD coordinates, in six degrees of freedom.

RoboTrack