TRITOP

Portable Optical Coordinate Measuring Machine

OPTICAL 3D COORDINATE MEASURING MACHINE

The portable TRITOP CMM system measures coordinates of three-dimensional objects quickly and precisely. Measuring tasks that were traditionally performed by tactile 3D coordinate measuring machines can now be carried out easily with the TRITOP CMM system. It does not require any complex, heavy, and maintenance-intensive hardware. The measuring machine comes to the object.

As with tactile coordinate measuring machines, TRITOP records the coordinates and their orientation in space for any feature of interest:

- Surface points and sections

- Primitives

- Holes, punch holes, and edges

- Diameters, lengths, angles ...

After the 3D coordinates have been determined, the measurement mathematically is transformed into the coordinate system of the component:

- RPS

- Gauge alignment

- Best-fit

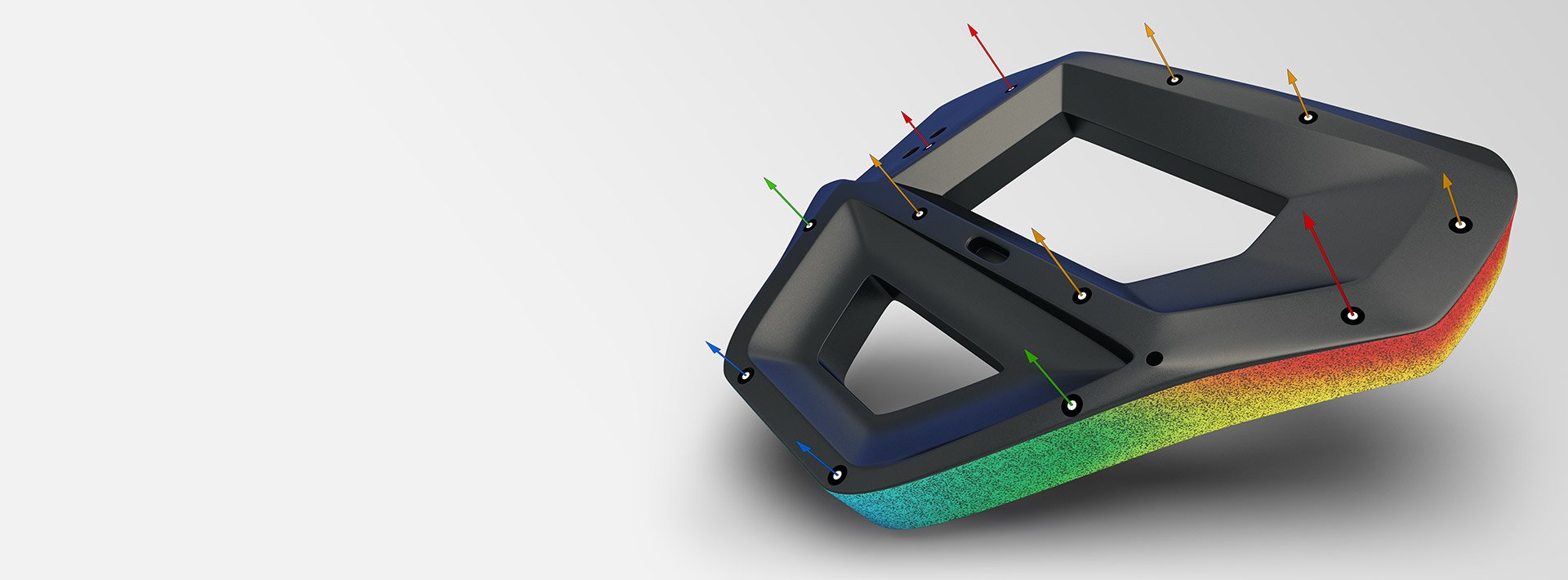

The measured and aligned data is used for various tasks:

- CAD comparison

- Verification of shape and position tolerances

- Verification of specifications from drawings, files, or tables

- Initial measurements

When comparing the measuring data with CAD data (IGES, VDA, STEP, Catia, ProE, UG), the corresponding measuring reports are created in the familiar formats:

- False-color representation

- Deviation of individual points as labels

- Sections, angles, and distances

- Diameters and flatness

- Tables and lists

Fields of Application

- Inspection of sheet metal parts and car bodies, e.g. in pilot production, process optimizing, tool try-outs, the start of series production, or during random samples

- Quality control of large objects, e.g. aircraft, ships, wind turbines, etc.

- Verification of plastic parts, e.g. for first article inspection

- Verification and recording of jigs and fixtures

- Measuring of models and prototypes, e.g. vehicle interior and exterior design

- Verification of tubes and wires with respect to their three-dimensional shape

- Measuring trimming edges of two-dimensional sheet metal blanks

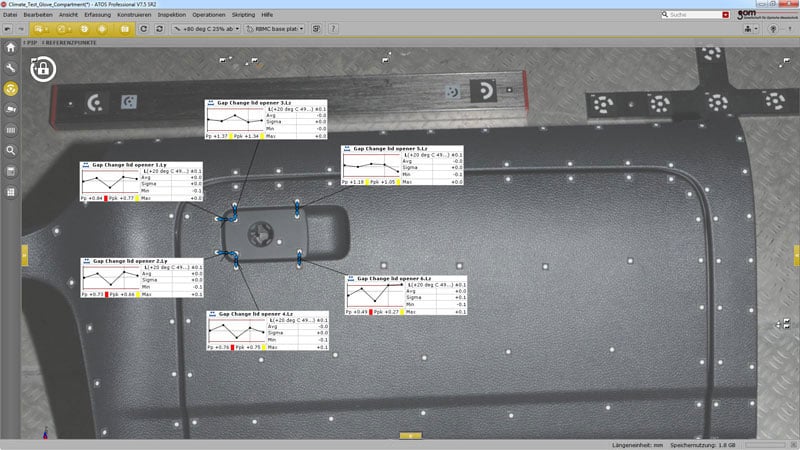

- Deformation analysis of the car and climatic chamber tests

- Measuring of reference point fields

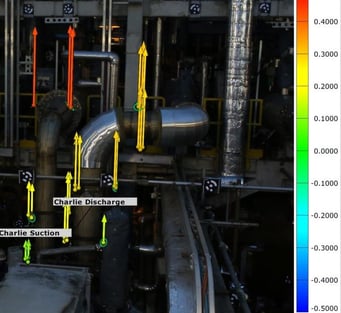

Static Deformation Analysis

TRITOP is an optical, mobile, measurement system, which accurately defines the 3D coordinates of object points at quasi-static conditions. Based on this information, TRITOP is capable of calculating 3D displacements and deformations of objects and components.

The non-contact TRITOP replaces conventional displacement measuring systems or LVDTs capturing displacements and deformations rapidly, without cables or sensors on or around the object. and therefore does not interfere with the object.

TRITOP provides for any number of measuring points information about:

- 3D Coordinates

- 3D Displacements

- Deformation

- Bending, Torsion, Deflection

- Rotation Angles

- 6 Degrees of Freedom

- Relative displacement (Point – Point, Point – Line, Point – Plane)

Fields of Application

- Climate Chambers

- Environmental Simulation

- Misuse Tests

- Stiffness Testing

- Gap Size Change

- Flush

- Verification and optimization of simulations

- Component deformation and testing

- Relative motion

- Global Strain

- Load tests and aging tests (force & temperature)

Application Note:

Thermal expansion measurement of large scale systems