Trilion Automation

Supercharge ZEISS INSPECT with our Scripting Suite

Python BASED

Simplify and automate any analysis workflow

Leverage our years of experience in scripting for the ZEISS ecosystem with our Suite of Add-ons

Automate your Workflow

Spend less time on learning workflows and focus on data analysis

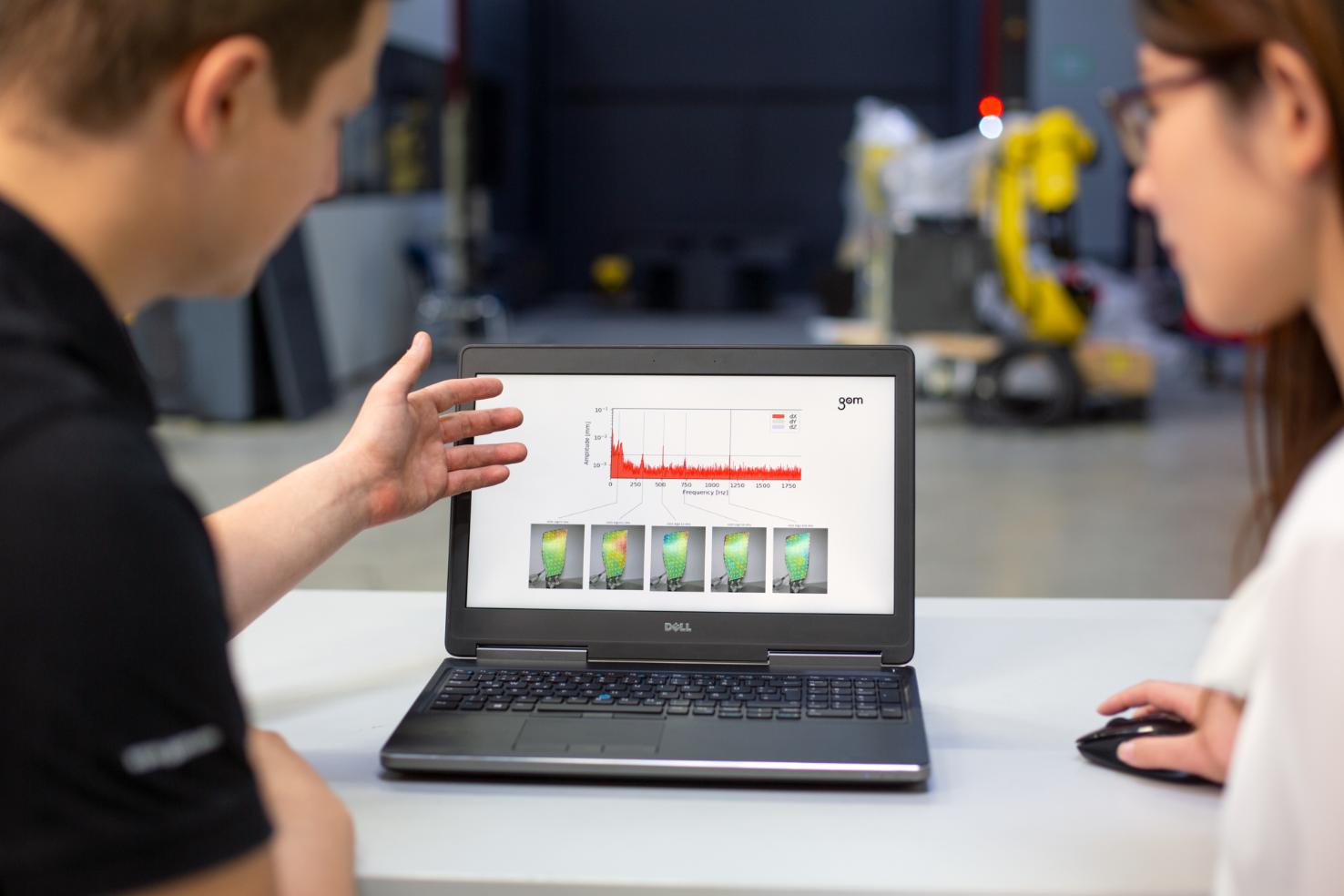

The Trilion Automation Suite is designed to seamlessly integrate with ZEISS Correlate and other Trilion products, offering a robust solution to streamline and automate various workflows. By significantly reducing the complexity of testing processes and simplifying data processing tasks, this suite enhances efficiency and accuracy. It empowers users to achieve faster, more reliable results while minimizing manual intervention, making it an indispensable tool for modern testing and data analysis environments.

Trilion Workflow Automation

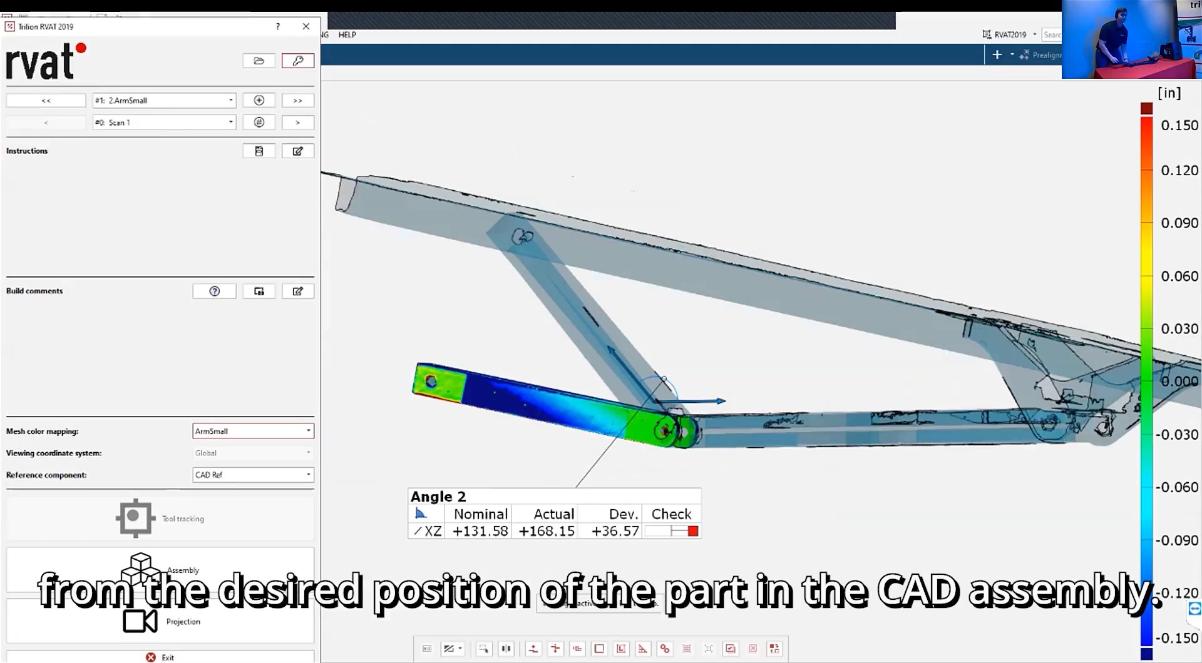

Each hole to be drilled is tracked to precise CAD dimensions, even on complex 3D parts, with Smart Tools. Blind holes can be drilled precisely, relative to reference structures, in true vehicle coordinates.

ARAMIS Automation Suite

60% faster than traditional hard tooling

QA (quality assurance) built-in

Precise positioning of components in 6-DoF (degrees of freedom)

Documenting as-built for your Digital-Twin

ARGUS

Automation Suite

The Digital Thread records the As-Built details, QA, and testing to complete the Digital Twin and store it on the RVAT Server for easy access and searchability.

Trilion Snap

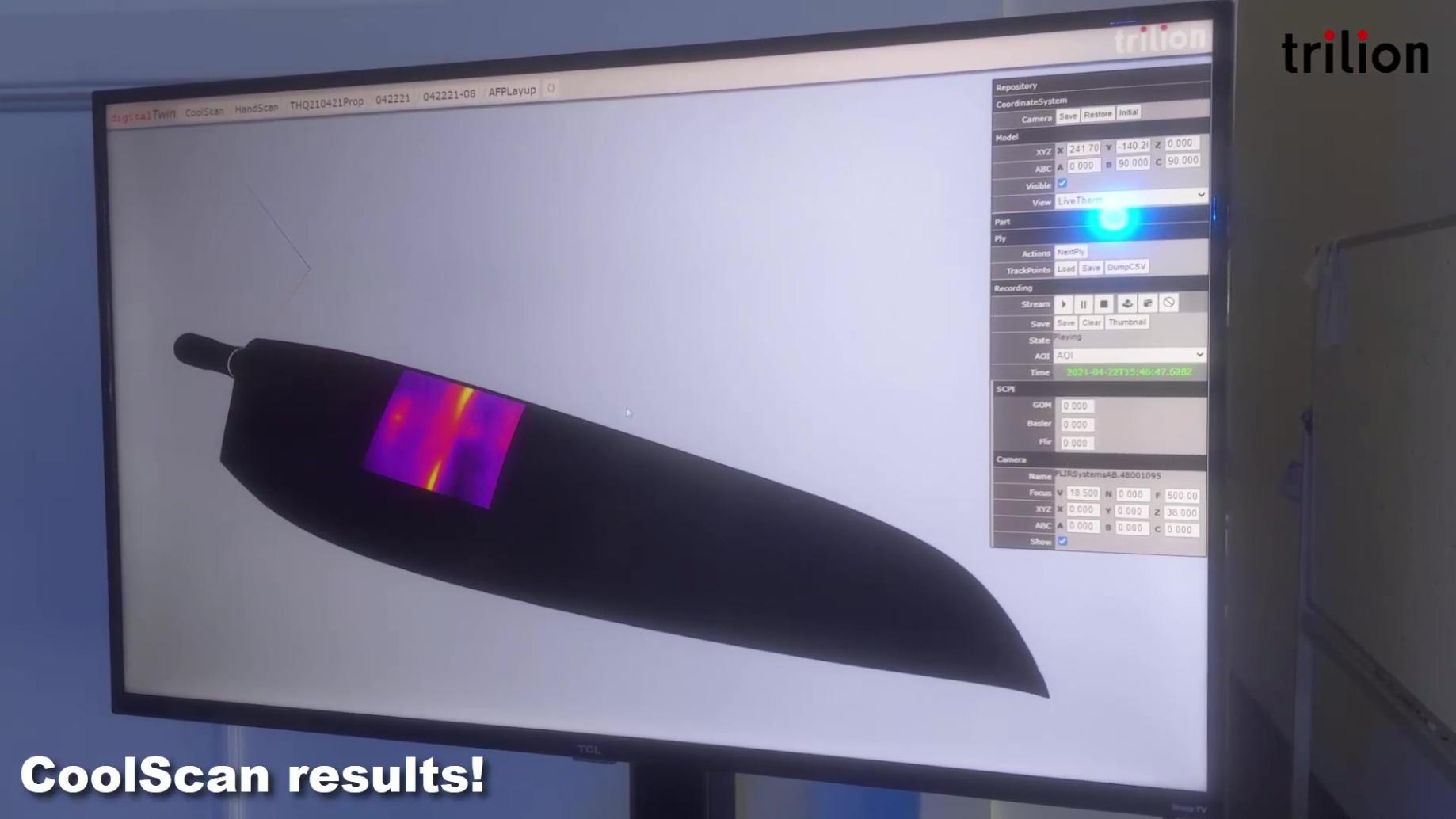

Voids, bridging and FOD can be detected before curing with our InSitu NDE during the layup to significantly improve product quality, ensuring high grade parts every time, and documenting these QA digital-threads for part validation.

Material Test Automation

Lap/gap, twist, porosity, voids and FOD can be detected in real-time with our InSitu NDE to detect problems during the AFP layup. There they can be immediately corrected to improve product quality and efficiency while reducing waste.

ARAMIS High-speed Automation

RVAT SmartTools allow the 3D optical tracking of standard or custom tools for precise positioning in true 3D CAD coordinates, in six degrees of freedom.

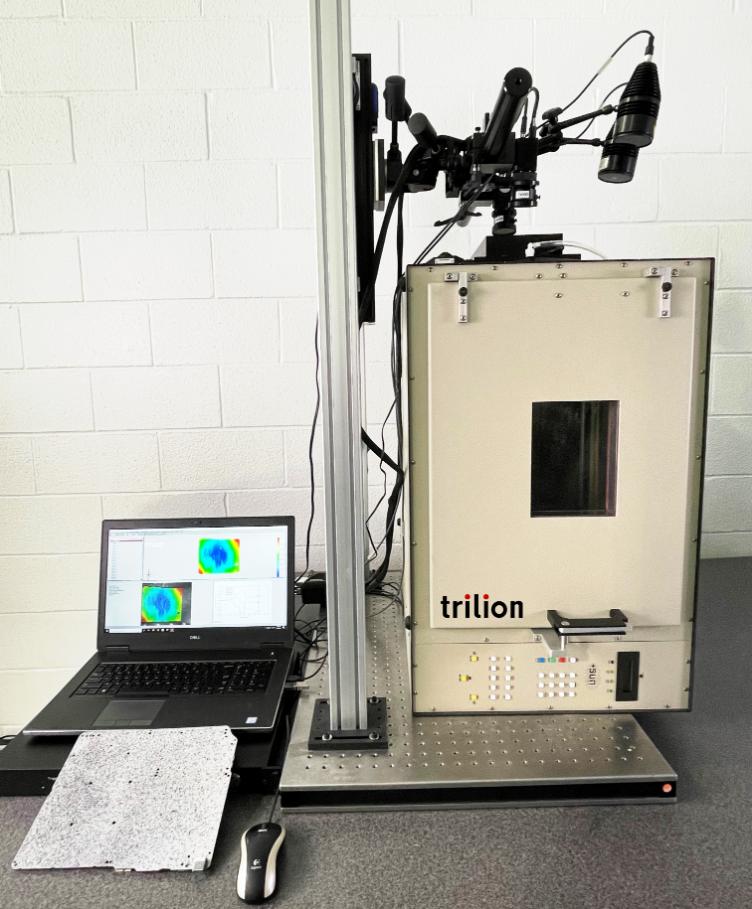

ARAMIS

Thermal Chamber